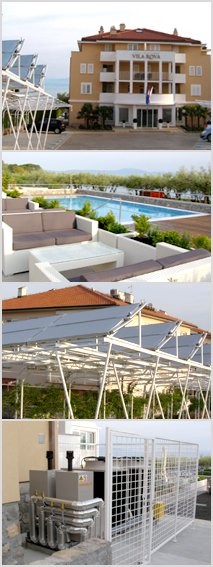

In the absorption technology of solar cooling the application of solar cooling has become the most discussed application. The reason for this is the use of solar radiation as the energy source of the drive that is free and renewable energy source. Thus this technology acquires the status of " Green energy". Also good circumstance of this technology is the simultaneous cooling demand and the available solar radiation (cooling during the day in summer).

Company Tehnokom as an authorized distributor of Yazaki - Maya , during the spring of the year 2014 supplied and installed complete equipment and commissioned the entire solar plant cooling business in the object " Vodovod Dubrovnik " in Dubrovnik.

The implementation of the EU project entitled " ADRIACOLD " financed from the EU IPA ADRIATIC - CBC , implemented by DURA so the city of Dubrovnik became the first city of the Adriatic region which has commissioned a solar plant for cooling the buildings.

The single-stage absorption refrigeration unit with working fluid water / LiBr nominal cooling capacity of 17.6 kW was embedded, manufactured by Yazaki - Maya - model WFC SC5 . The system works optimally with heating water temperature of 88 ° C. The system produces cold water temperature 6/12 ° C. Installed capacity of the cooling device is 0.05 kW .

As a source of heating it is used energy solar field of six batteries at three vacuum collector product Vissmann Vitosol 200 - T of the total absorption area of 60 m2 . For removal of waste heat from the refrigeration unit is installed wet cooling tower performance 40,7 kW .

The received energy of the sun across the plate heat stored in the heat storage tank volume of 3 m3 , and by circulation pumps leads to the absorption unit. Cold water from absorbing device is supplied in an existing building installation of fan oil. On the cold side is integrated inertial tank volume of 1 m3. Due to the necessary security as a parallel security system for cooling, it is used the existing heat pump of cooling capacity 14.64 kW, which optionally includes the work.

To heat the building in winter, heating is also provided by the existing heat pumps heat output 16.11 kW. At a time when the solar field provides enough energy for heating it uses energy from the solar field.

Full property operation of the heating and cooling controls the automatic regulation. The project incorporated the necessary measurements of various technical parameters of the cooling system, solar collector systems, and environmental parameter, as required under the EU project " Adriacold ".

This concept plant is used in summer and winter, by that it is achieved that apsorption cooling is in continuous operation for over 5 months, which contributes to the high efficiency of the plant.